Non-Woven Fabric Whole Plant Machinery & Equipment

Single Machine for non-woven fabric manufacturing:

- Air-Through Oven

- Carding Machine

- Feeding Machine

- Needle Punch Machine

- Opening Machine

- Slitting Machine

- Thermo-Bond Machine

- Winding Machine

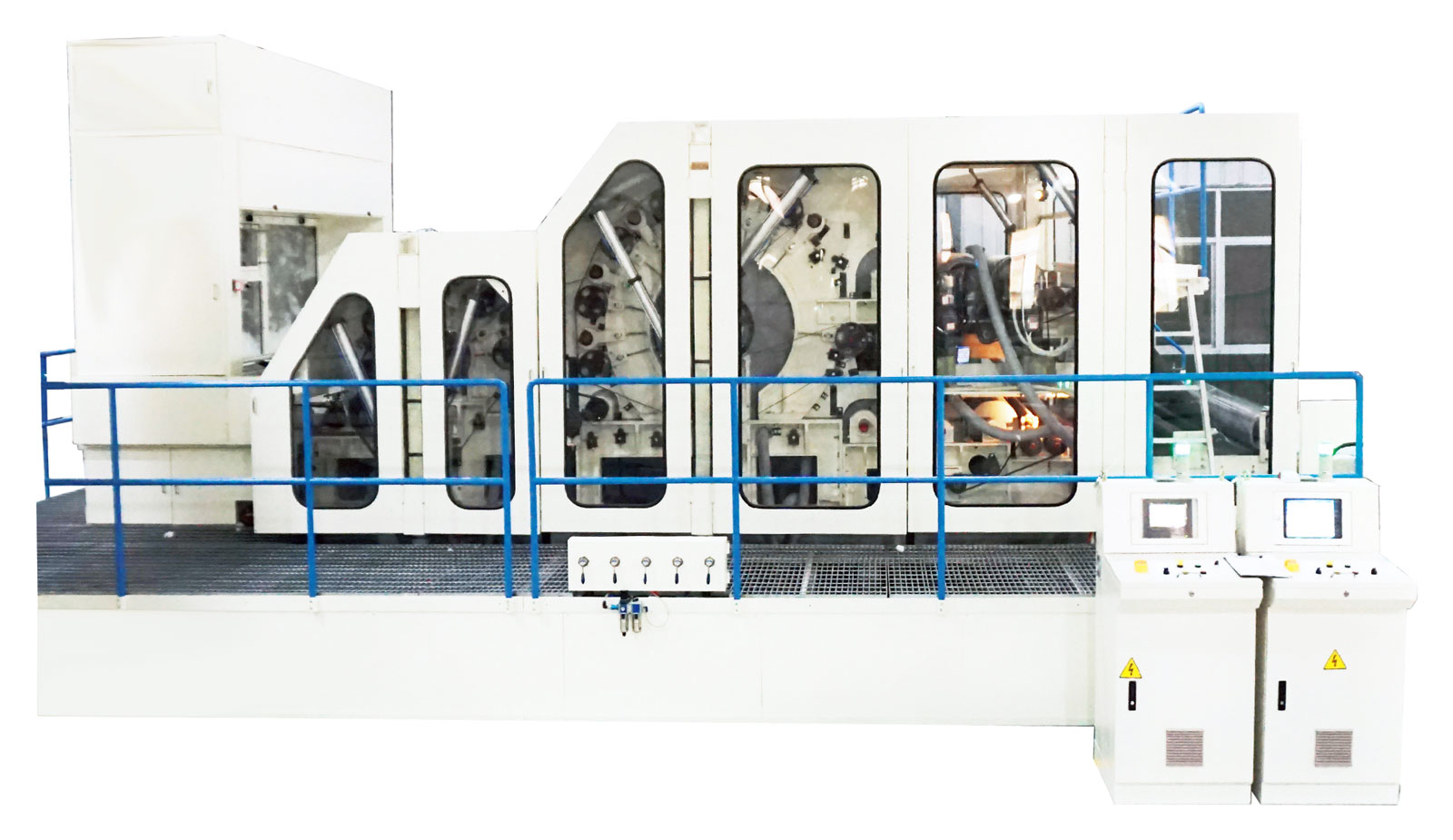

Production Lines:

- Air-Through Production Line

- Needle Punch Production Line

- Thermo-Bond Production Line

- Wadding Production Line

Air Through Oven

- It's a hot air bonding process

- Working width: <3600mm

Features

Entrance equip with bellow type mesh guiding device, easy and clean. Inside air flow chamber is with left and right blow in design to make sure the entire horizontal air flow uniformity.

Each chamber left middle right air flow is adjustable. At the exit is equip with air cooling system and chilling water cooling roller.

Carding Machine

- The fiber layer feed from the chute feeder card with different size wire mount roller and form fiber web for the next bonding process.

- Working width: <3000mm

Features

Suitable for carding 1.2D-20D fiber.

With different types of carding machine: Single cylinder single doffer, Double cylinder double doffer, with random roller, condense roller, web take off with fly comb or roller, feed in, doffer and condense roller with inverter speed change, with metal detector device.

Blending Machine

- To give more better blending with the fiber open up by the opener and a purpose of storage to keep continuous production

- Working width: 2000mm-3000mm

- With rotate blowing device

Opening System

Electric Weighting Opening System

- Compose: Several bale openers, Pre-Opener, Blower, S Shape magnet.

- Suitable for various types of fiber for weighting ratio purpose.

Vertical Type Opening System

- Compose: 2-3 Bale openers, Opener, Blower, S Shape magnet.

- Suitable for single type of fiber.

Chute Feeder

- Main purpose is to feed uniform fiber layer to the carding machine control by stable air pressure.

- Working width: <3000mm.

Features

Up and down reserve space is a easy controllable air pressure for fiber compactness, down reserve space with air flow gates to control horizontal uniformity.

Fiber Reserve Tank

- Main purpose is store fiber to keep continuous feeding to the chute feeder

- Working width: 1400mm

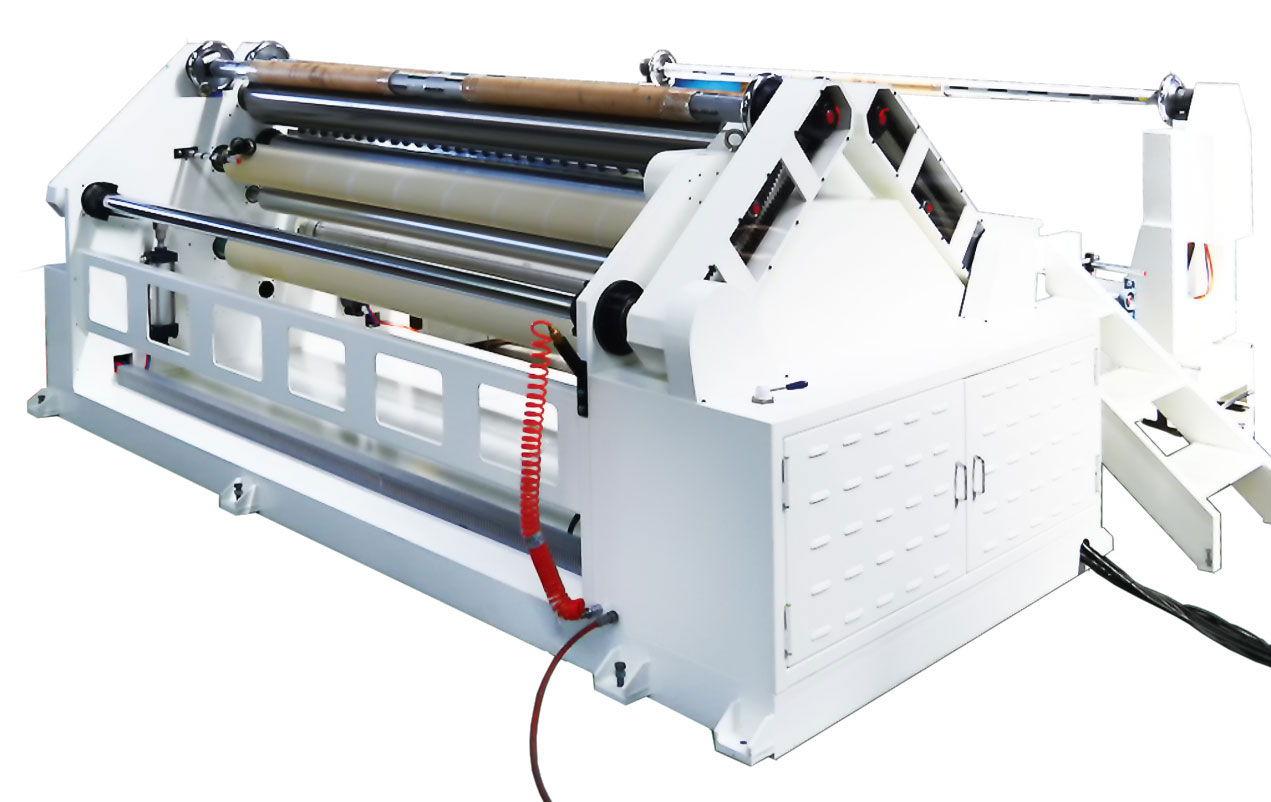

Slitting Machines

Single shaft slitting machine

- Slit the jumbo roll into need length and width.

- Working width: <3600mm.

Double shaft slitting machine

- Slit the jumbo roll into need length and width.

- Working width: <3600mm.

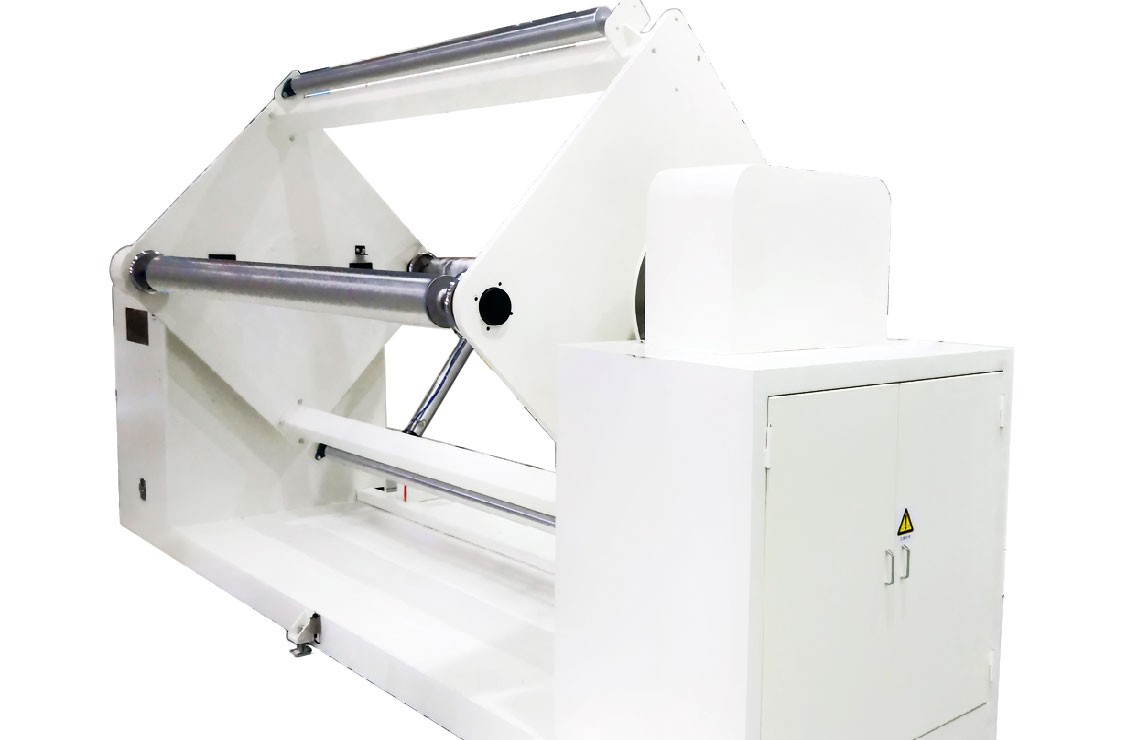

Winding Machines

Single shaft surface winder

- Wind up the nonwoven fabric into jumbo roll.

- Working width: <3600mm.

Features

Stable wind up tension, automatic meter count roll change, suitable for diameter over 2M.

Double shaft center winder

- Wind up the nonwoven fabric into jumbo roll.

- Working width: <3000mm.

Features

Stable wind up tension, automatic meter count roll change, suitable for diameter below 2M.