Spunmelt Composite Lines SMS, SMMS, SMMS, SSMMS

SMS Spunmelt Composite Line

Combine the spunbond and meltblown technologies in one line. Spunbond + Meltblown + Spunbond.

Joining spunbond and meltblown webs together for the final laminated web to attain the optimum properties of high strength of spunbond and barrier and filtration properties of meltblown webs produce SMS laminates. This composite structure is tremendously successful as they can be engineered to high strength products. A SMS laminate comprises of an internal layer of meltblown fibers sandwiched between two layers of spunbond filaments of PP and PE.

Overview of the SMS Product Line

SMS Process Flow Diagram

Main Specifications of SMS Spunmelt composite line

| Effective Width (mm) | SMS 3200MM LINE | SMS 2400MM LINE | SMS 1600MM LINE | |

|---|---|---|---|---|

| SMS | Output (tons/year) | 7000 | 5200 | 3500 |

| GMS range (g/m2) | 10-100 | 10-100 | 10-100 | |

| Max. speed m/min | 400 | 400 | 400 |

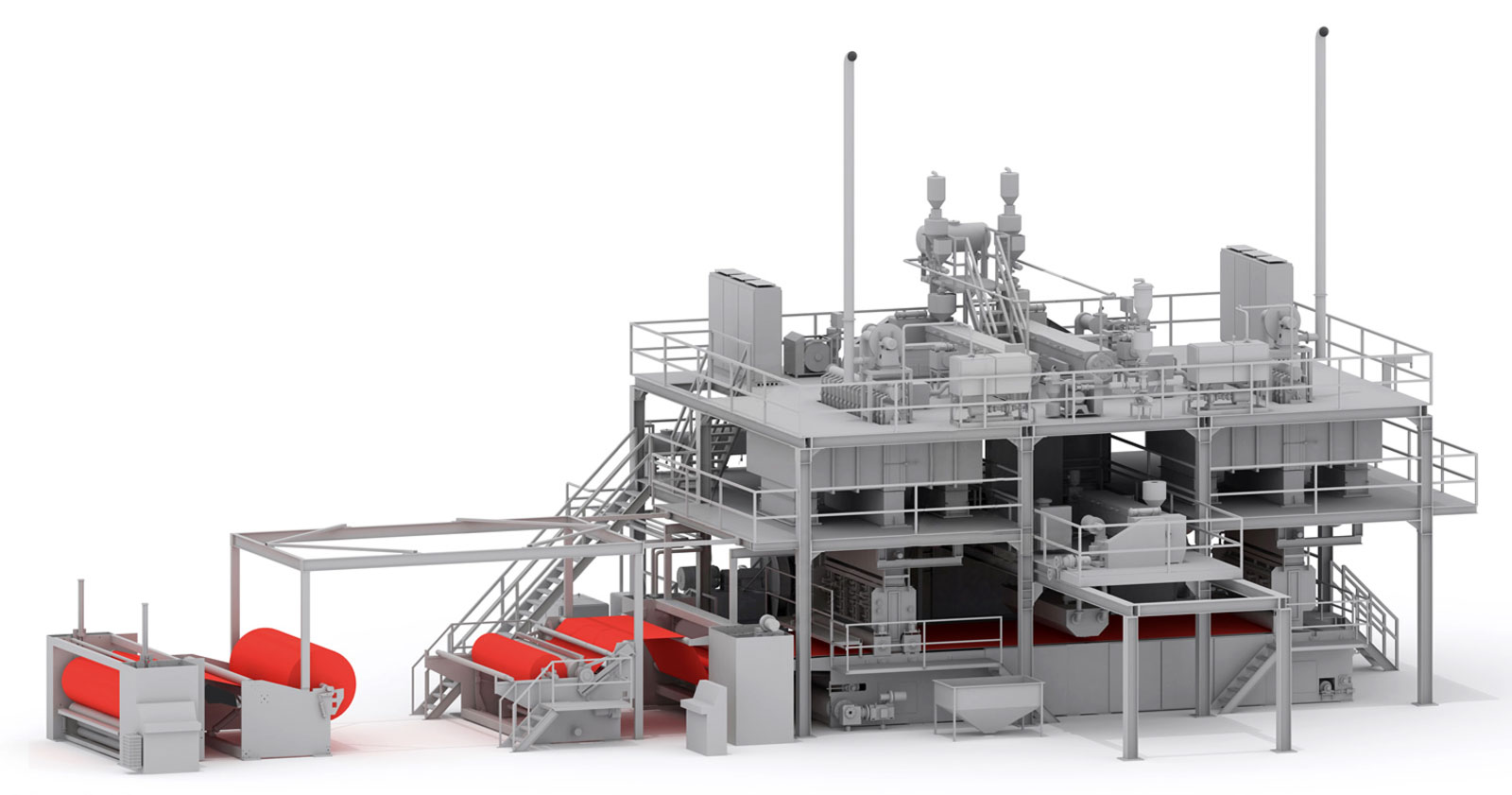

Installed SMS Non Woven Fabric Production Line

SMMS Spunmelt Composite Line

The SMMS is four layer nonwoven; two layers of meltblown nonwoven is sandwiched between two layers of spunbond, like the SMS Nonwoven fabric, the meltblown nonwoven here is doubled. The SMMS is more symmetry, water repellency, bacterial resistance and durability than SMS.

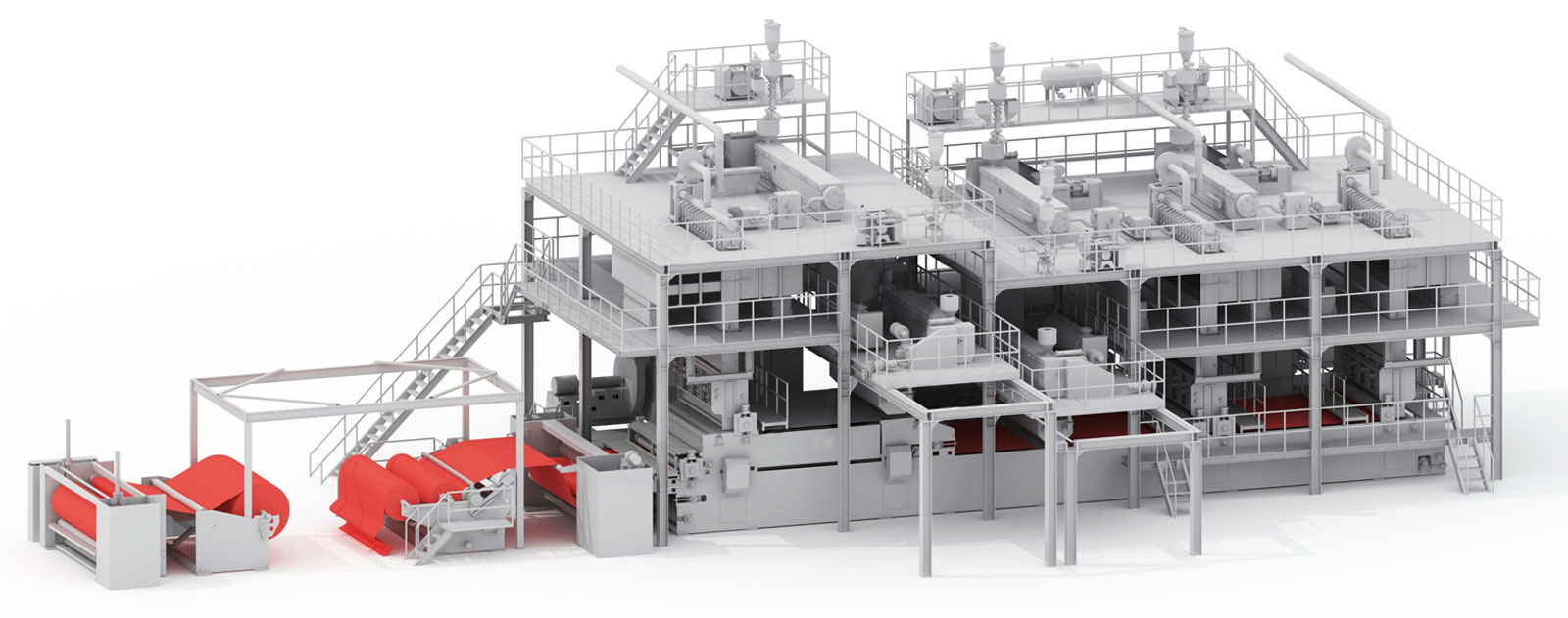

Overview of the SMMS Non Woven Fabric Production Line

SMMS Process Flow Diagram

Main Specifications of SMMS Spunmelt Composite Line

| Effective Width (mm) | SMMS 3200MM LINE | SMMS 2400MM LINE | |

|---|---|---|---|

| SMMS | Output (tons/year) | 8000 | 6000 |

| GMS range (g/m2) | 10-100 | 10-100 | |

| Max. speed m/min | 450 | 450 |

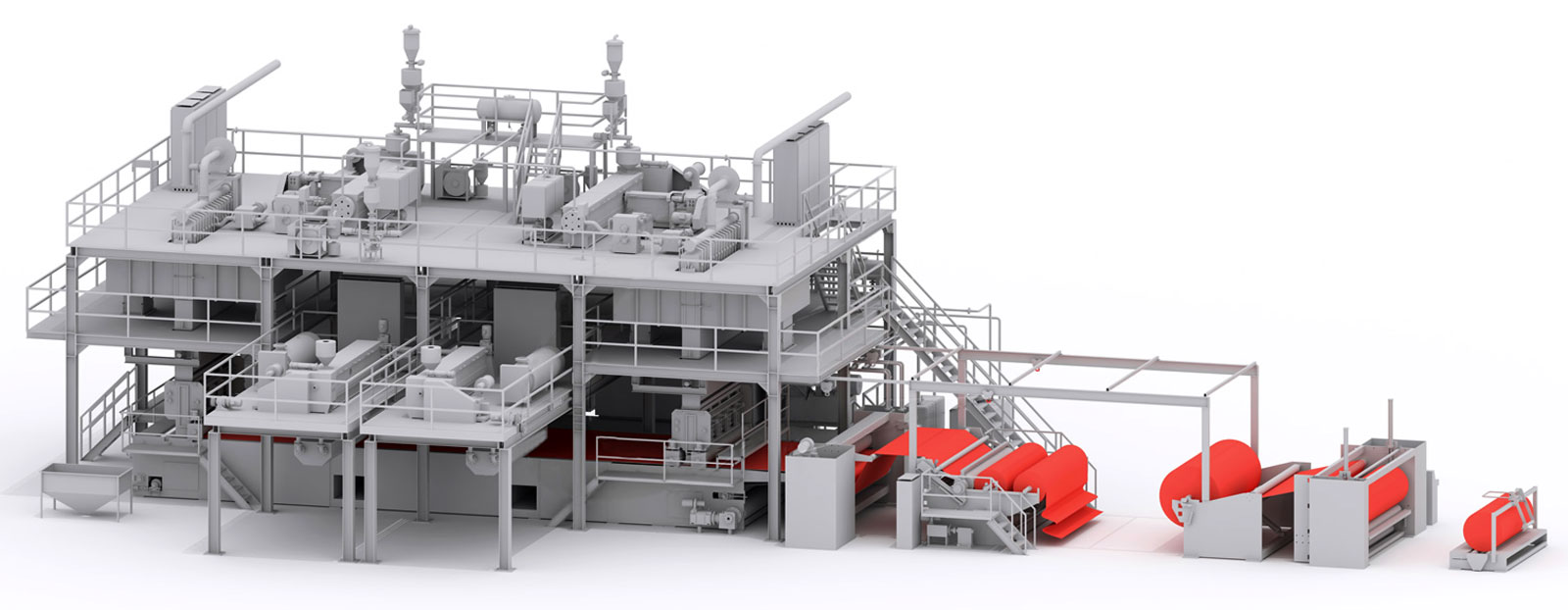

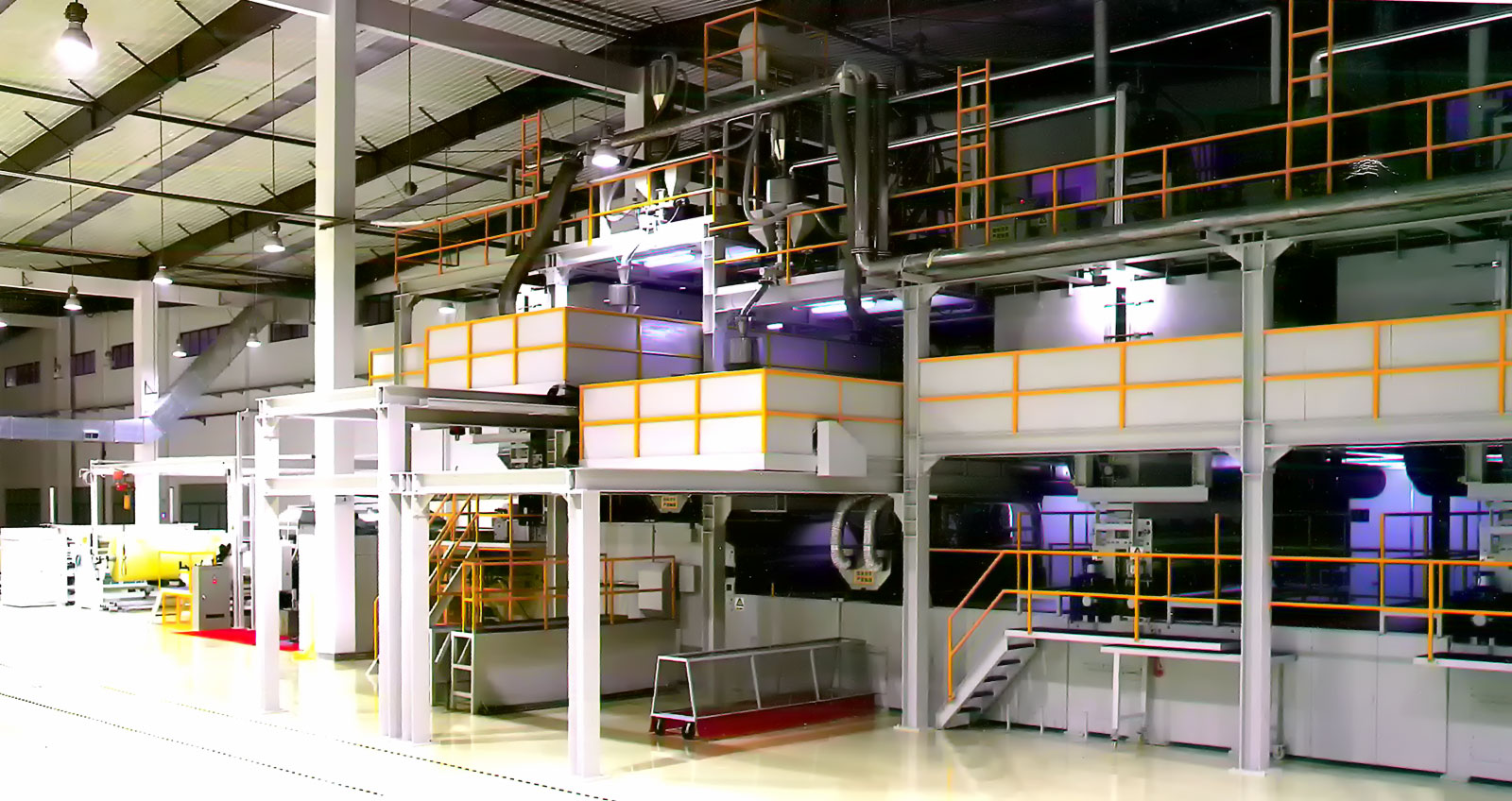

Installed SMMS Non Woven Fabric Production Line

SSMMS Spunmelt Composite Line

SSMMS structure comprises of three spunbond layers interlaid with two meltblown layers.

Overview the SSMMS Product Line

SSMMS Process Flow Diagram

Main Specifications of SSMMS Spunmelt composite line

| Effective Width (mm) | SSMMS 3200MM LINE | SSMMS 2400MM LINE | |

|---|---|---|---|

| SSMMS | Output (tons/year) | 10000 | 8000 |

| GMS range (g/m2) | 10-100 | 10-100 | |

| Max. speed m/min | 600 | 600 |

Installed SSMMS Non Woven Fabric Production Line

Applications of Spunmelt Non Woven Fabrics

Nonwoven medical products

- Surgeon's mask

- Surgical drapes

Nonwoven hygiene products

- Baby and adult diapers

Combinations with other nonwovens / fabrics

- Paper composites

Work protection

- Protective clothing

- Breathing masks