Sanitary Napkin Production Lines

Sanitary Napkin Machine W0 (Second hand)

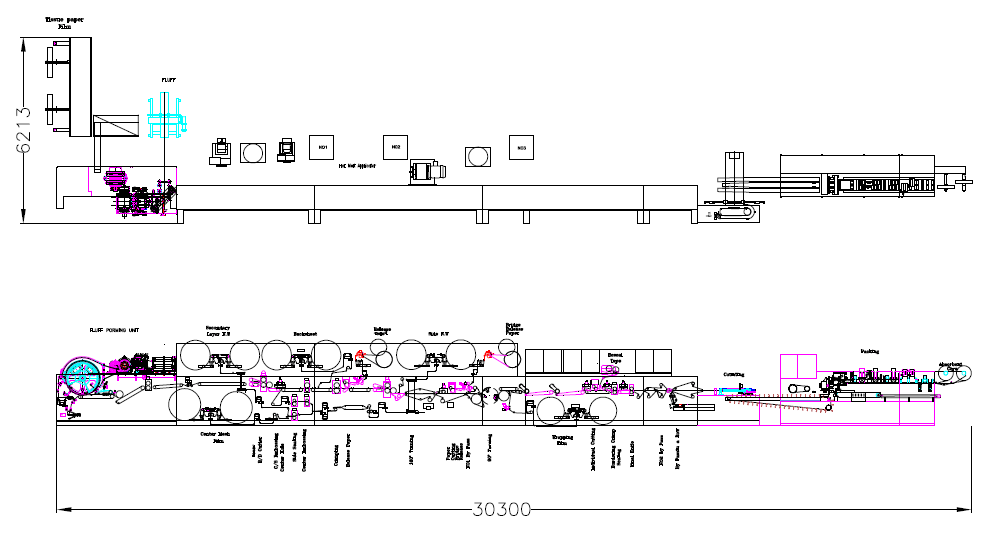

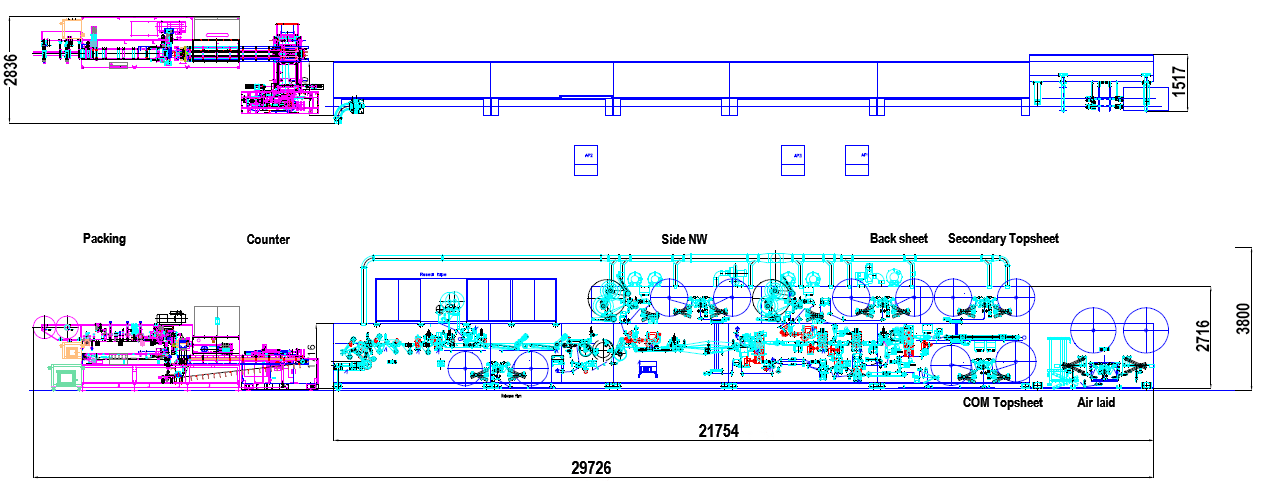

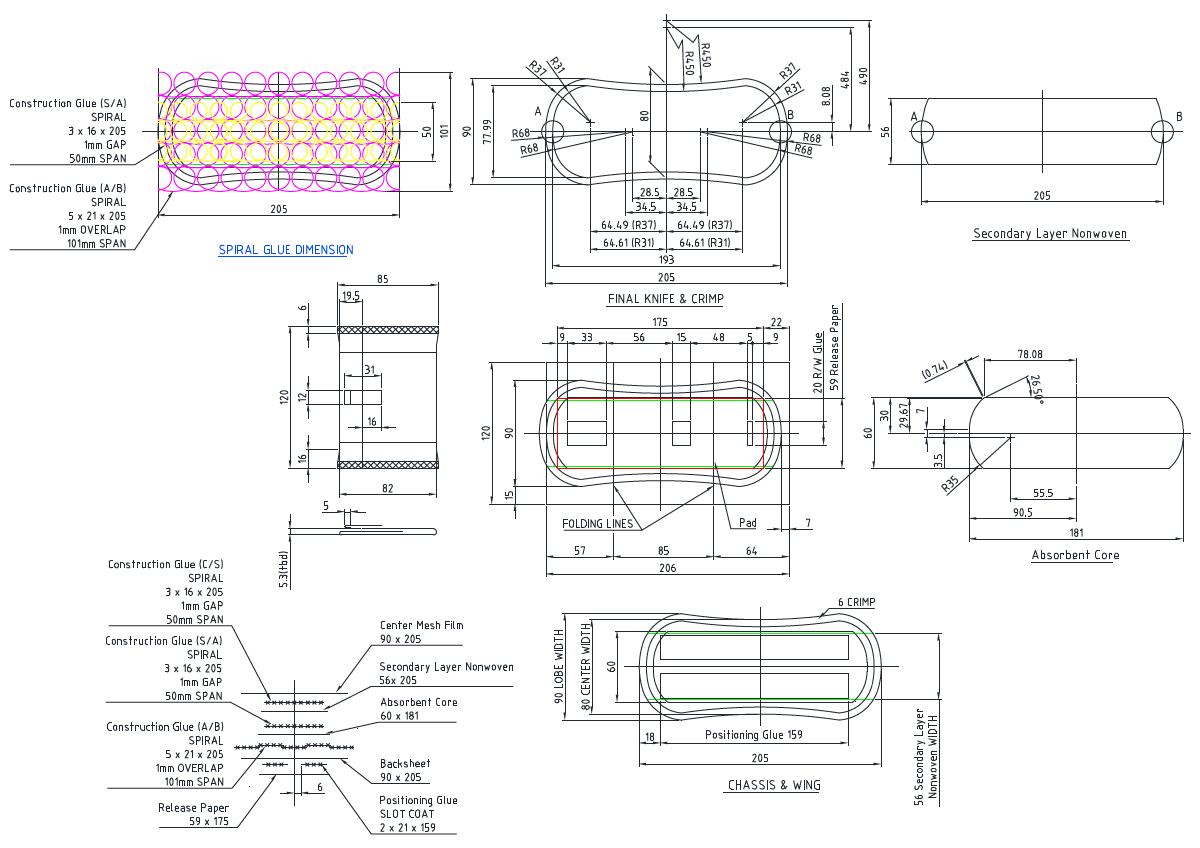

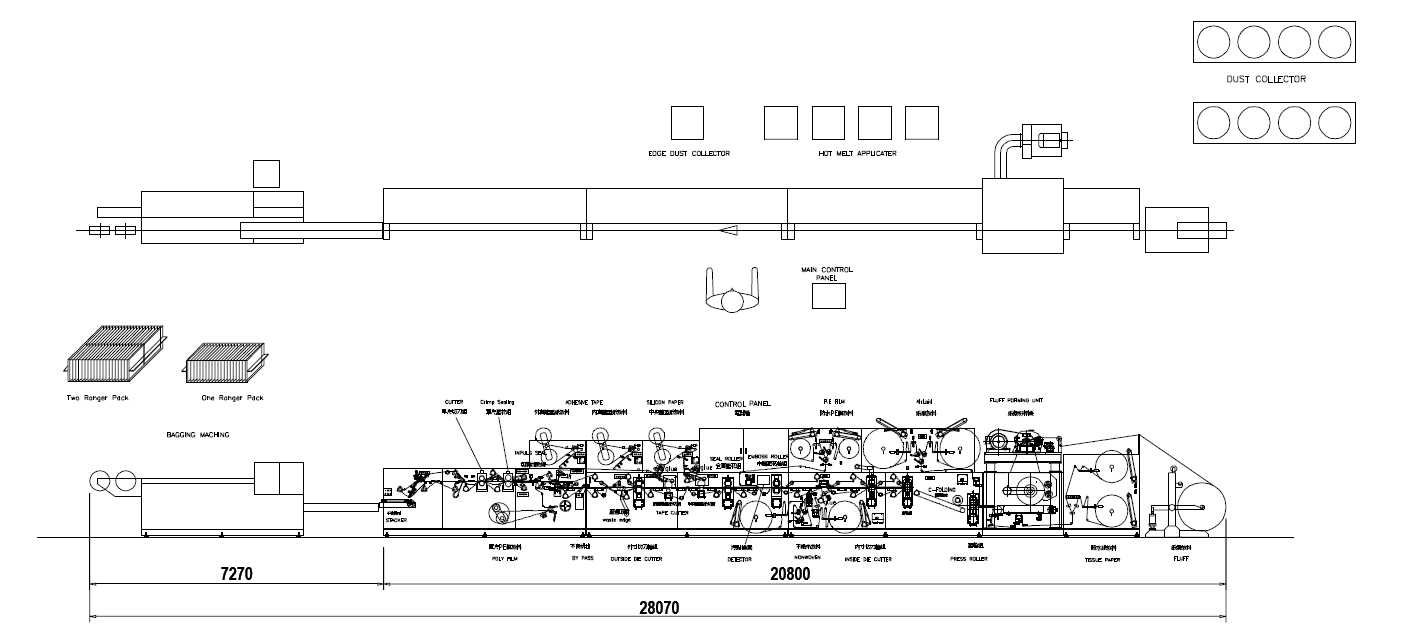

Machine production process flow

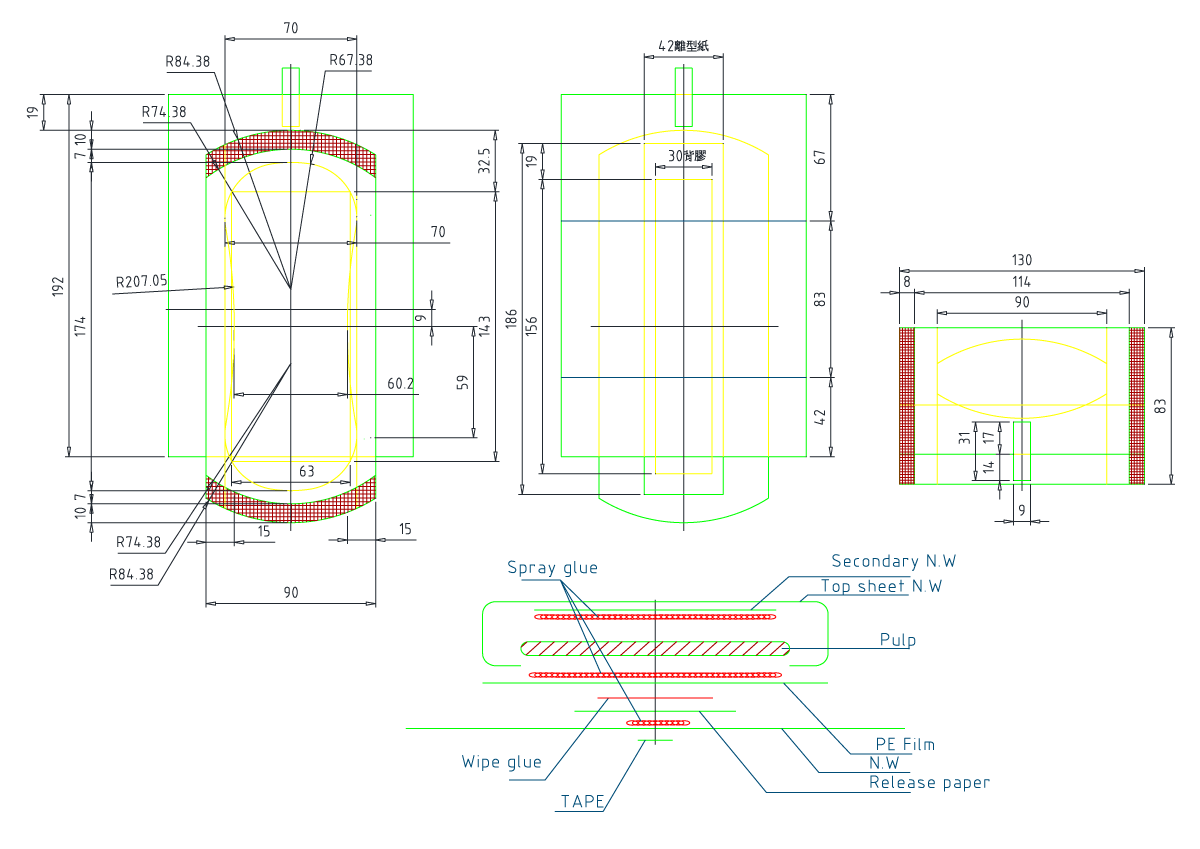

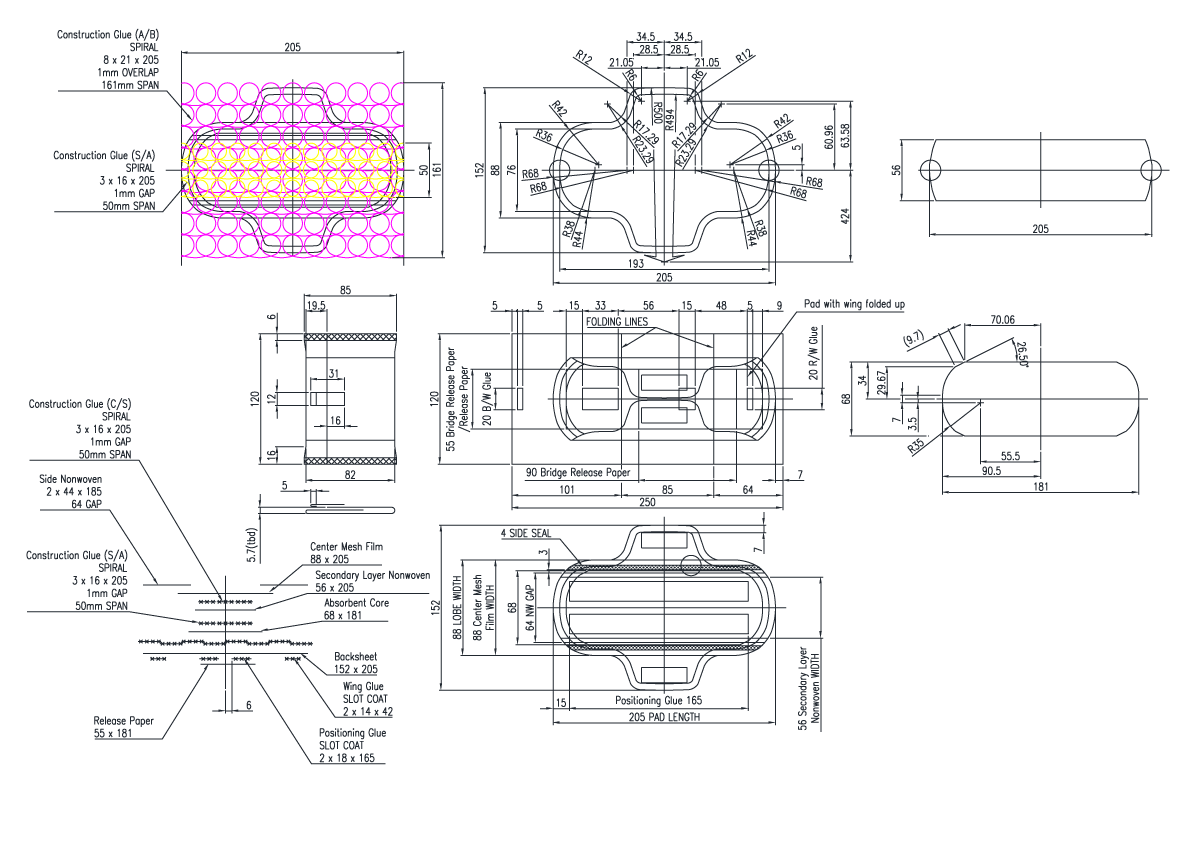

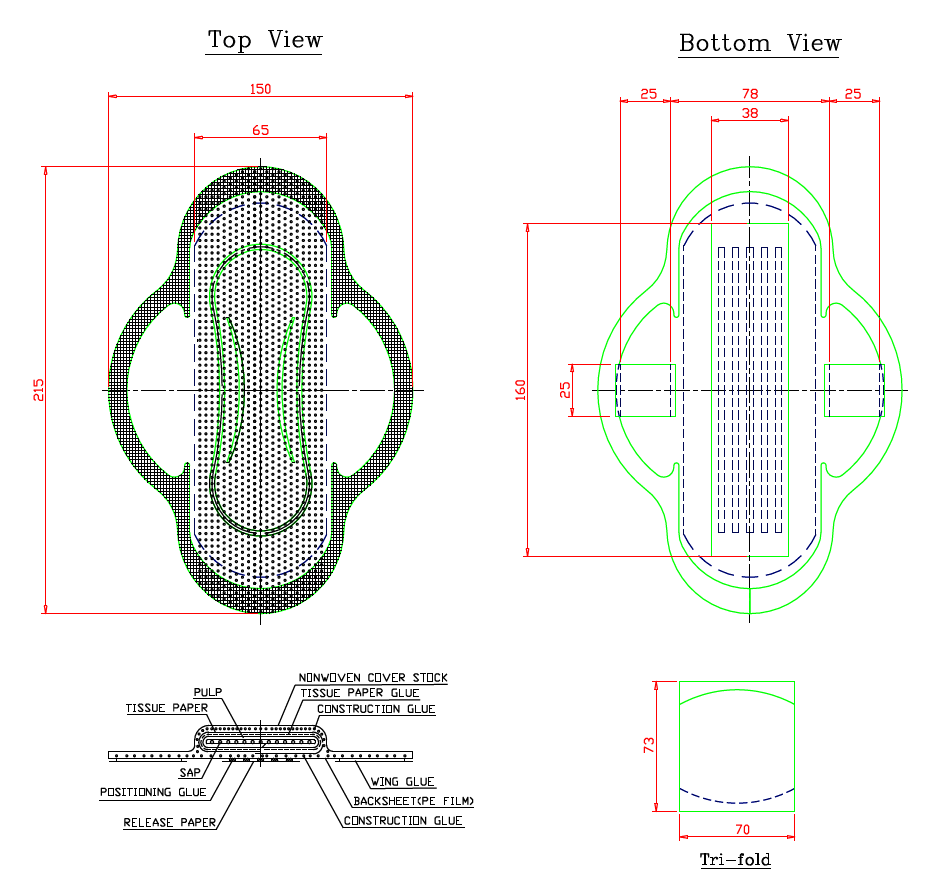

Product picture

Main Technical Specification

| Parameter | Value |

|---|---|

| Produce specification | 205 mm |

| Design line speed | 700 pcs/min |

| Produce line speed | 600 pcs/min |

| Uses electric power | 333 kW |

| Voltage | 3 Phases 3 Line 220V, 50/60Hz |

| Air pressure source | 0.5 MPa (Max 0.7 MPa) |

| Machinery size | L(34M) × W(8M) × H(4M) |

| Machine control system | Servo motor & PLC system |

Sanitary Napkin Machine W1 (Second hand)

Machine production process flow

Product picture

Op1

Op2

Main Technical Specification

| Parameter | Value |

|---|---|

| Produce specification | 205 mm |

| Design line speed | 700 pcs/min |

| Produce line speed | 600 pcs/min |

| Uses electric power | 175 kW |

| Voltage | 3 Phases 3 Line 220V, 50/60Hz |

| Air pressure source | 0.5 MPa (Max 0.7 MPa) |

| Machinery size | L(33M) × W(8M) × H(4M) |

| Machine control system | Servo motor & PLC system |

Sanitary Napkin Machine W2 (Second hand)

Machine production process flow

Product picture

Main Technical Specification

| Parameter | Value |

|---|---|

| Produce specification | 205 mm & 205 mm |

| Design line speed | 550 pcs/min |

| Produce line speed | 450 pcs/min |

| Uses electric power | 190 kW |

| Voltage | 3 Phases 3 Line 220V, 50/60Hz |

| Air pressure source | 0.5 MPa (Max 0.7 MPa) |

| Machinery size | L(29M) × W(8M) × H(4M) |

| Machine control system | Servo motor & PLC system |

To be affected by Buyer

- Resources of electric power, water and compressed air etc.

- Primary and secondary side electrical power, cable and ducts.

- All pipe for water and air.

- Hoist, cranes, forklifts and related equipment used to install and maintain the equipment.

- Various lubricants, greases and heat transfer oils needed for the first time operation of the equipment.

- Technical service: The installation is included start-up and will be carried out under the supervision and with the co-operation of our experienced technicians. The customer must provide the necessary number of skilled helpers and tools. Round trip airfare, local transportation, meal, and accommodation will be borne by customer.

- Test materials: Buyer will supply all the raw materials for run test at buyer’s plant.