PP Spunbond Non-woven Machinery

Introduction

This line is the professional non-woven fabric manufacturing equipment. It is featured with lower investment, compact construction, small area, simple production technology, simple operation, saving of labour and widely compatibility and so on.

Overview

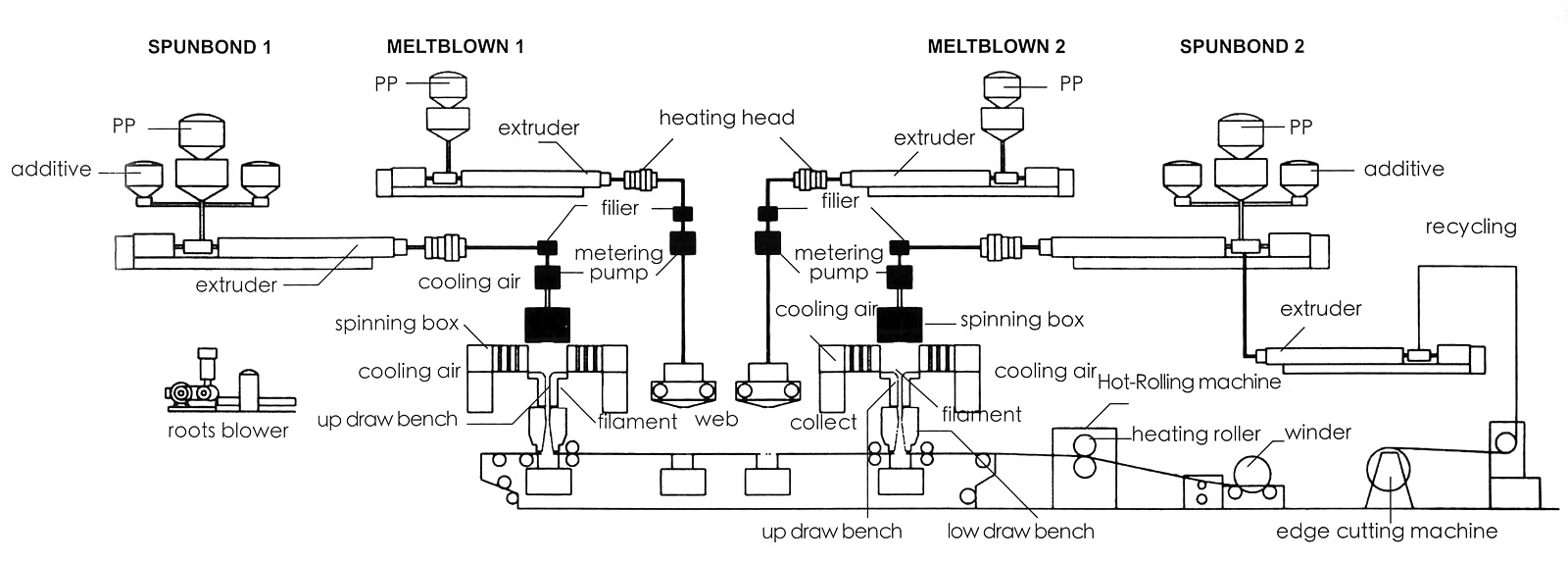

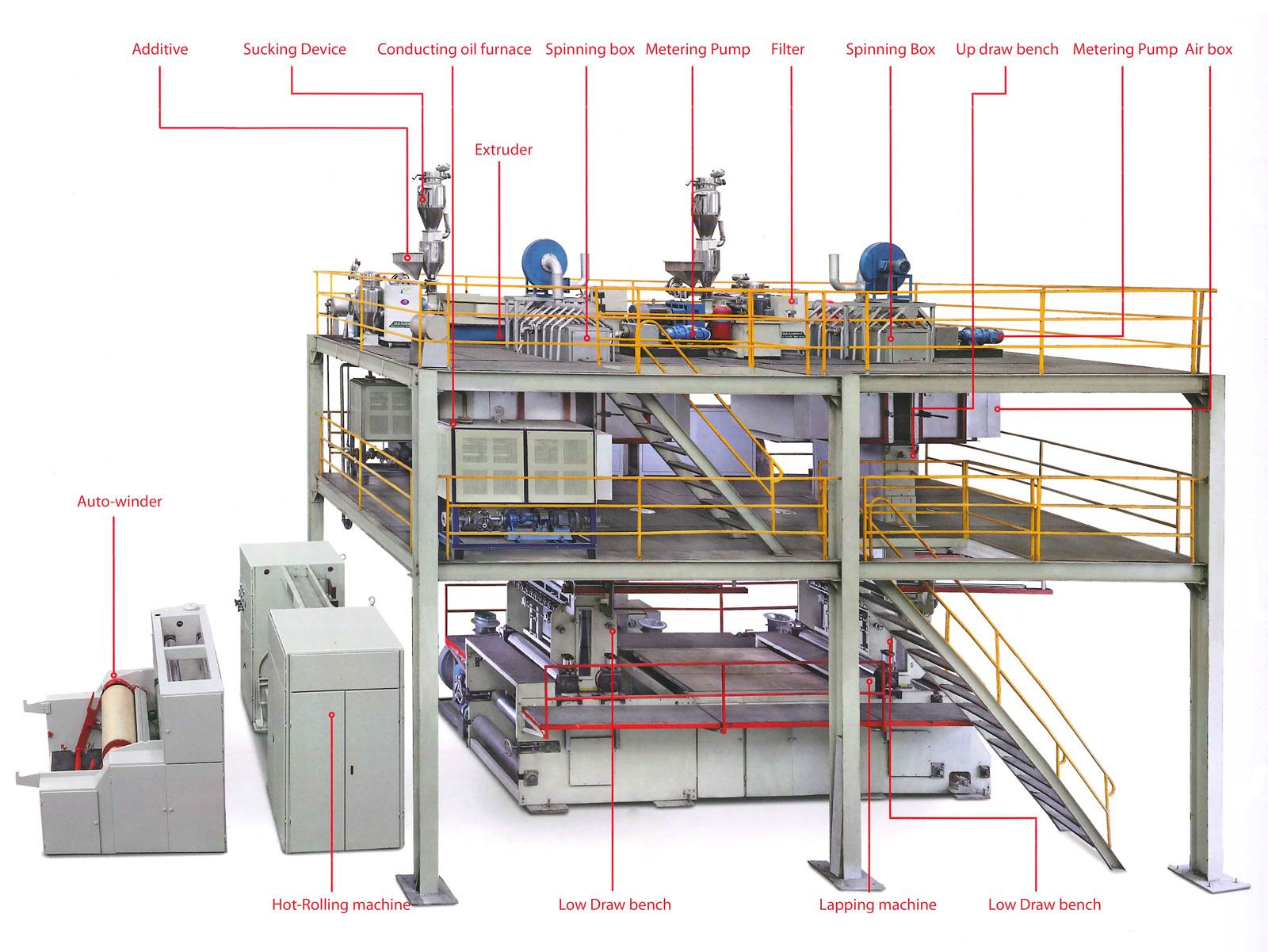

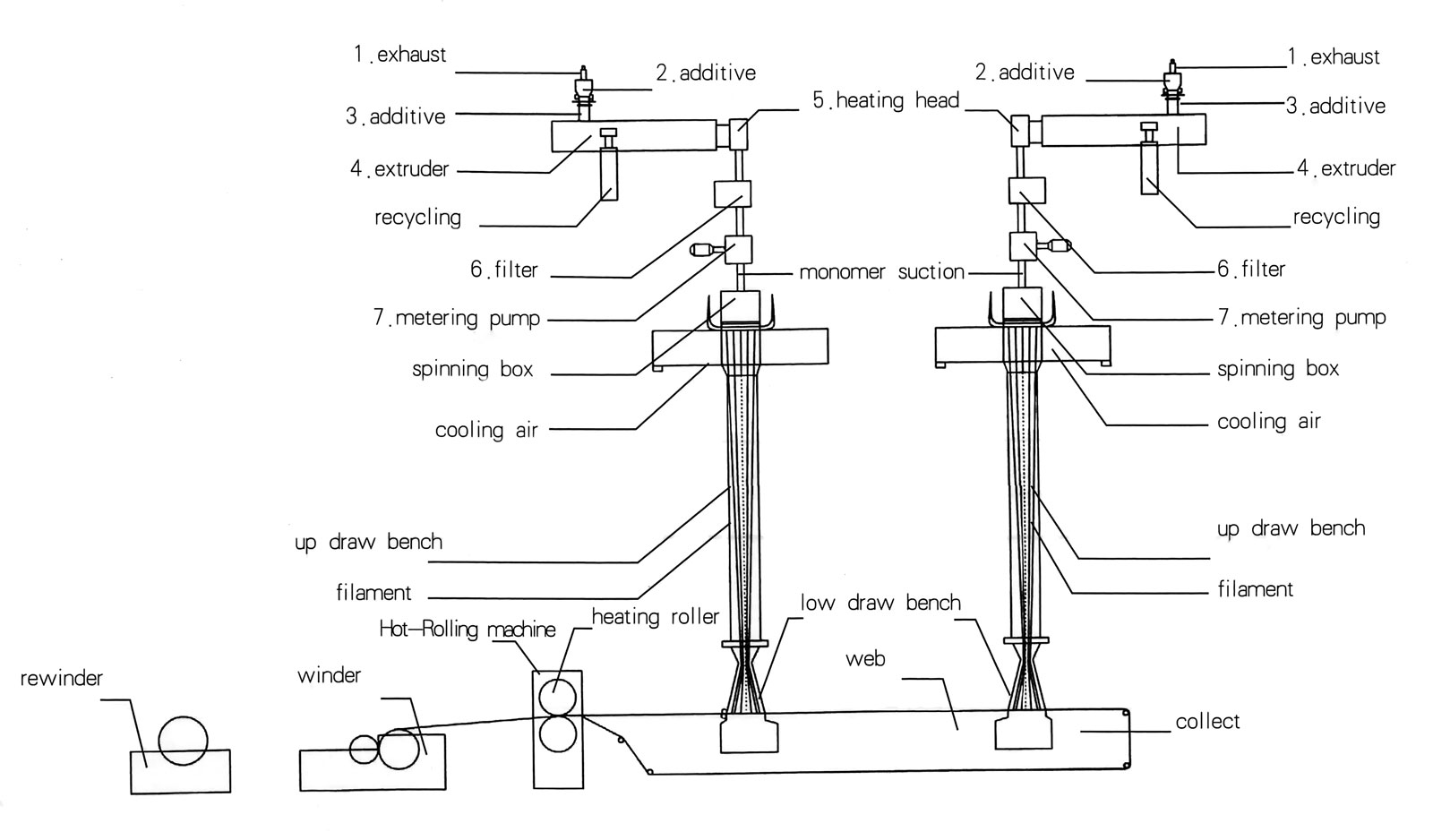

Flow Chart

PP Spunbond Production Line Technical Parameter (standard specification)

| ITEM | EFFECTIVE WIDTH | GSM | ANNUAL OUTPUT | EMBOSSING PATTERN |

|---|---|---|---|---|

| S | 1600mm | 10-200 | 1680T | Diamond, oval, cross and line |

| S | 2400mm | 10-200 | 2600T | Diamond, oval, cross and line |

| S | 3200mm | 10-200 | 3500T | Diamond, oval, cross and line |

| SS | 1600mm | 15-150 | 2800T | Diamond, oval, cross and line |

| SS | 2400mm | 15-150 | 3700T | Diamond, oval, cross and line |

| SS | 3200mm | 15-150 | 6000T | Diamond, oval, cross and line |

| SMS | 1600mm | 15-150 | 3360T | Diamond and oval |

| SMS | 2400mm | 15-150 | 4440T | Diamond and oval |

| SMS | 3200mm | 15-150 | 7200T | Diamond and oval |

| SMMS | 1600mm | 15-150 | 5000T | Diamond and oval |

| SMMS | 2400mm | 15-150 | 7000T | Diamond and oval |

| SMMS | 3200mm | 15-150 | 9000T | Diamond and oval |

Flow Chart

Technical Advantage

- ) The whole line is well-structured and easy operating.

- ) The whole line is highly automated.

- ) Control elements are of well-known make, high performance and reliable technologies.

- ) The whole line is controlled by PLC and operated with touch screen

- ) The allocation of the main frame auxiliary equipment can be specially designed and adjusted according to customers requirement.

Glue spraying Lamination equipment for nonwoven fabric (optional)

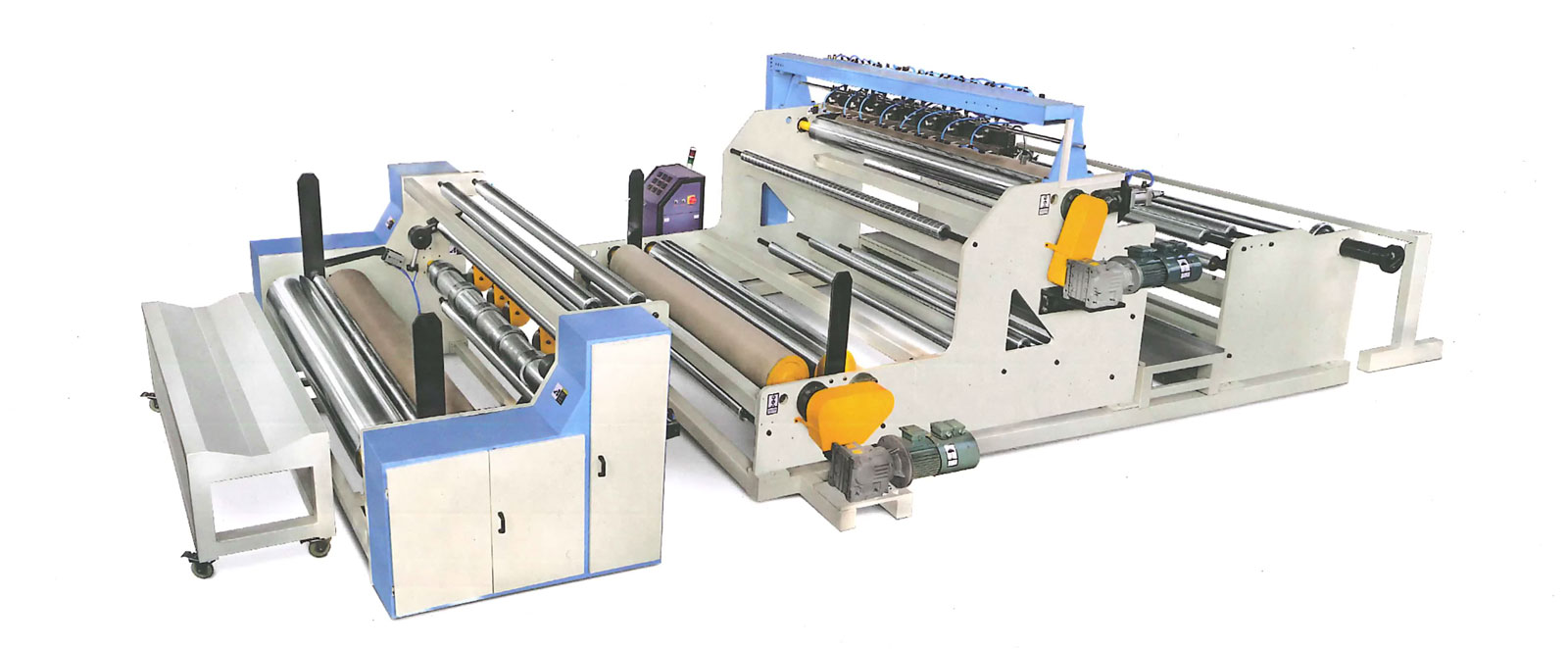

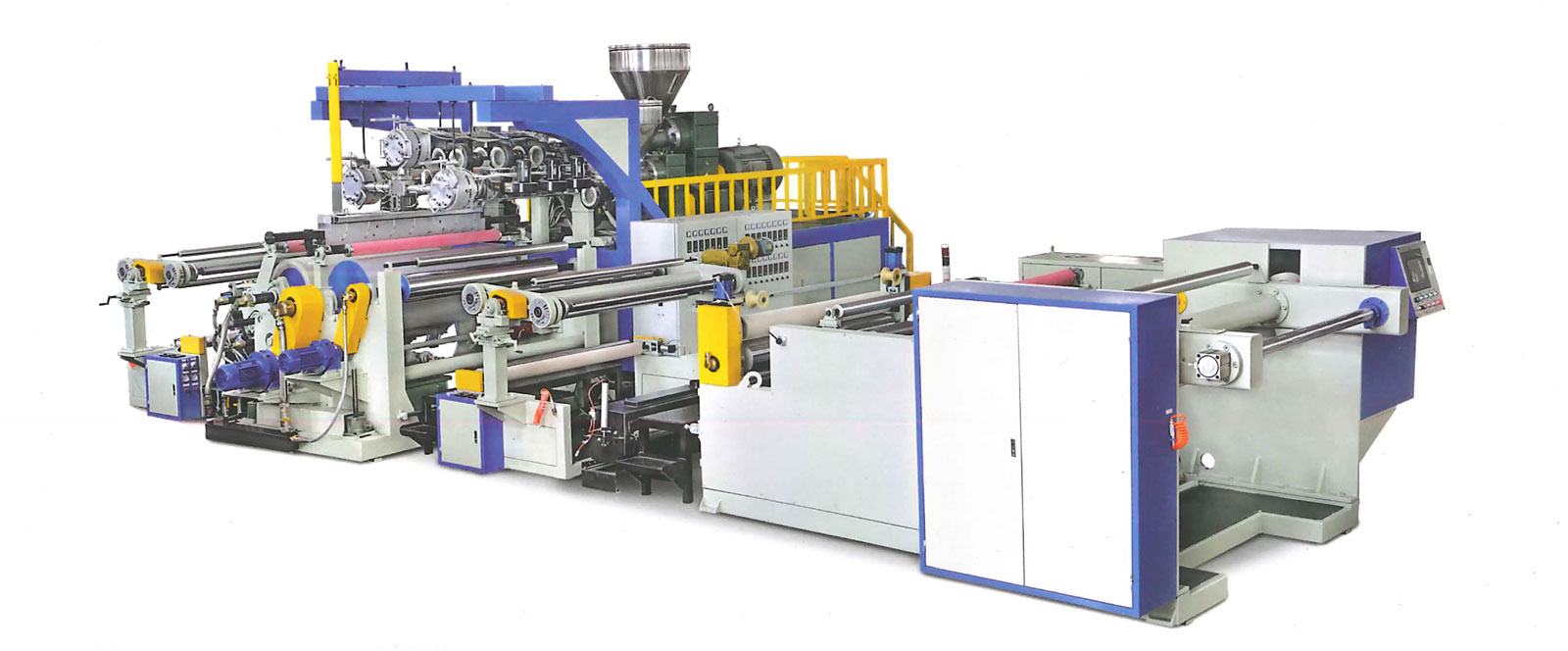

Lamination and Laminating Combination Machines (optional)

Description

According to different orders and usage, Lamination and Laminating Combination Machines can finish the works of one-layer lamination, double layer lamination or laminating combination of two or more layers of base-materials. These machines have been widely used in doing laminating or combination for nonwoven fabrics, paper, film, plastic sheet, textiles and a lot of composite materials, which modifies functions and adds value to products in industries such as food, packaging, advertising, daily consumption, health care, medical industry, and construction industry, etc.